What is Tyre Retreading?

When a tyre loses a few millimeters of its tread it doesn’t have to be thrown away, but it has to be brought to a new life, as it still maintains its specific structural qualities unimpaired. Eliminating and replacing the worn out tread, the tyre can be given back features completely similar to the original one

Moreover, every year Customers choosing to use retreaded tyres save money and protect the environment. To build a truck tyre 70 kg of rubber are needed for the production of which 100 liters of oil are needed. If the tyre is not retreaded after its first use, this amount of raw materials would be lost through disposal. Instead, by retreading, it is re-covered in great part, adding only a limited quantity of raw materials to replace the worn out tread

Benefits of Tyre Retreading

Reduction in oil use-The data shows that 21 gallons of oil are used to produce one new tyre.

While only 7 gallons of oil are used to produce each retread tyre. This means that 14 gallons of oil are saved each time a company chooses a retread tyre over the equivalent new tyre option.

Limits the number of tyres in landfills-The number of tyres now in landfills is now at over 800 million. And the data shows that re-using tyres before they become scrap products can help to reduce the landfill impact by a factor of three to four.

Re-use post-consumer material-The material comprising the tyres can also be used more effectively when used in the tyre retreading process. They contain 75% post-consumer material, ensuring that material that would otherwise not be available for use in the marketplace is now reworked back into the production process.

A growing industry-Tyre retreading is now a quickly growing industry across the globe. The studies show that 13 million tyres are retread annually, ensuring that their materials remain out of the local landfills and are used more effectively to help companies support their environmental initiatives.

The economic benefits-Beyond the environmental benefits; there are many business advantages to consider when reviewing tyre retreading. Growing fleets across the country are now generating significant economic value simply by turning to retreading over new tyres.

Reduced fuel costs-Retread tyres offer superior fuel-efficiency compared with lower quality foreign made new tyres.

Lower cost per tyre-The retread tyre costs about 10 to 15K less per tyre than the average new tyre, helping growing fleets reduce their capital investments significantly.

Tread Belts

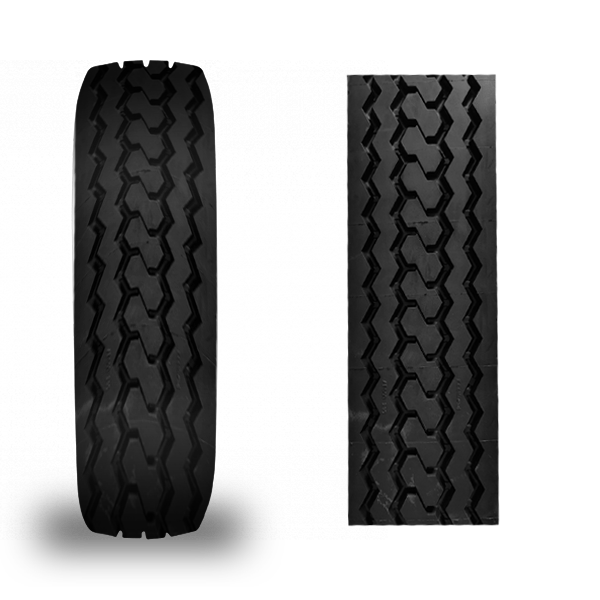

AFS

Used for nylon tyres, front pattern.

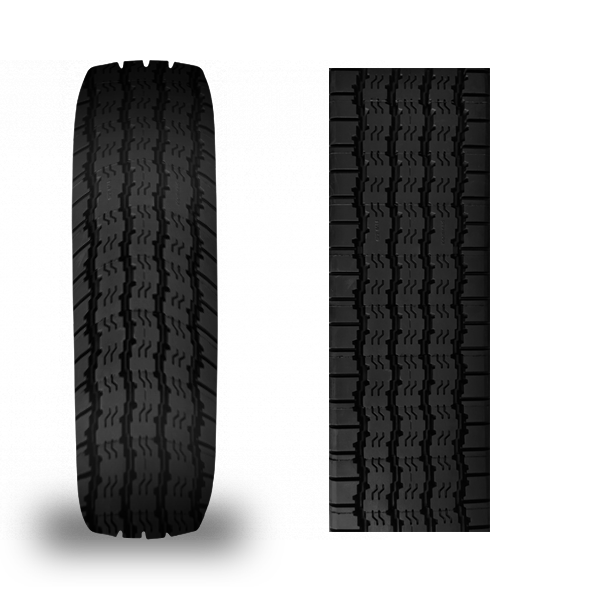

TZT

Used for radial tyres, rear pattern.

TZYL

Used for radial tyres, primarily used as front pattern. But could be used in rear tyres as well, based on application.

TDE3

Used in radial tyres. Rear pattern.

T159

Used in radial tyres. Primarily used as front pattern, however could be used in rear tyre as well, based on the application of the tyre.

LL

Used in radial tyres for special applications, such as mining. Also known as mines pattern.